TROUBLESHOOTING BAD RUNNING

Although more specifically aimed at the Kawasaki Z650/Z900/Z1/Z1000 linage of aircooled bikes with Mikuni slide carburettors. However, this advice given should still be applicable to other motorcycles.

Many owners of the classic air cooled Kawasaki fours may encounter issues with the correct running of their bikes, such as:

- Uneven or erratic tick over

- Surging

- Flat spot just off idle

- Bogging

- Sooty spark plugs

- Spitting back

- Revs hanging

It will often be a combination of multiple issues leading to inconsistent running. Below is a list of all the items that can contribute and where issues are found, should be rectified:

Electrical system

The coil input voltage needs to be at least 11.5v for a nice fat spark. You may also find that your coil voltage drops lower when you turn on the headlight. This is usually caused by degraded wiring within the harness, corroded connectors or bad earthing.

However, it's also crucial to ensure that you have the correct Stator/Alternator output, your charging system (regulator and rectifier) is operating correctly and your battery is working as it should.

Many people find it beneficial to install the Wired George relay mod. This modification provides battery voltage directly to the coils via a relay.

Ignition system

Check that your ignition timing is set correctly, your points and condensors are in good condition, with the correct gap and your advancer is working as expected. Always check your timing dynamically using a strobe.

The later models with factory electronic ignition are generally less troublesome than points systems. Many owners replace the points setup with the Dyna S pickups. These still use the original mechanical advance unit.

It's not advisable to use resistor spark plugs and caps - just use one or the other.

Note that there are lots of fake NGK spark plugs in circulation and these cause running issues. We'd suggest you try the equivalent Denso plugs instead.

Some people have noted that you should avoid mixing sets of points from different manufacturers as this can lead to variable ignition as the metal in the points spring can expand at different rates in each set of points.

Coils, leads and spark plugs & caps

As mentioned above, it is essential to have at least 11.5v input to the ignition coils, but ageing coils can and do break down leading to a reduced spark. Sometimes they may not break down until they get hot. The input and output leads can also degrade leading to erratic performance. Check the connection between the leads and plug caps and ensure that the caps are in good shape.

Also, don't use resistor plugs and resistor plug caps as this can reduce the spark to your plugs.

Compression

The factory specification is a minimum of 105PSI and no more than 15PSI variance between any two cylinders on the Kawasaki 903 and 1015cc bikes. A widely varying compression between cylinders is more likely to cause inconsistent running than when all cylinders are more uniformally low.

Low compression is usually caused by incorrect valve clearances, badly worn valve guides or valve seats, worn or damaged bores, rings or pistons.

Without removing the cylinder head the only thing you can check and adjust are the valve clearances. Tight or no valve clearance results in a loss of compression and can lead to damaged valve and seat faces.

Valve timing

Due to a misinterpretation of the instructions in the factory workshop manual it is common to find engines setup with the valve timing out by one tooth. This doesn't normally cause any physical damage but does cause poor running.

Air intake system

Check that the carb to head inlet rubbers are in good shape and properly sealed to the cylinder head. Also ensure that the clamps to carbs are correctly tightened.

Check that you have the correct airbox and air filter. Make sure the lid clips down securely and has seals that actually work. Make sure there are no holes or cracks in the airbox body - it's common to see airboxes with holes drilled in them to improve airflow.

Also check that the carb to airbox rubbers are correctly fitted, have no splits and the retaining bands are nice and tight.

If your bike includes an airbox silencer, then ensure this is fitted. We have seen some bikes which don't run correctly without them.

Fuel system

As the fuel system is gravity fed it is essential to check that your petrol tank is correctly venting. Check that your petrol tap is allowing fuel to flow sufficiently and that the internal filters are intact and free of debris.

Also, ensure that your petrol tank is rust and debris free on the inside. We would always suggest fitting good quality inline fuel filters, as even the smallest bit of crud can cause problems.

Carburettors

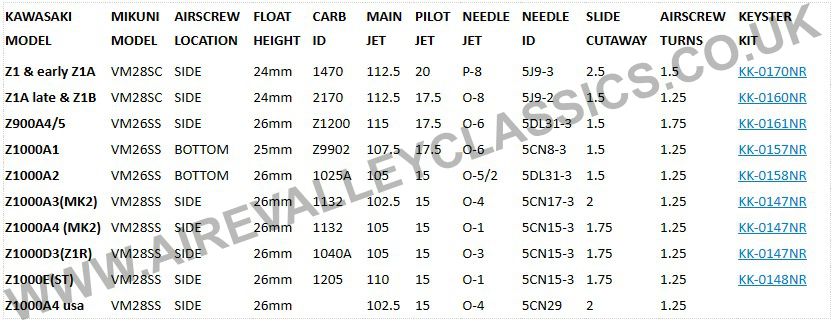

Are you sure you have the correct carbs fitted to your bike, with the correct jetting, needles and slides?

Use this list to cross reference your carbs and their internal specifications.

** NOTE **

Z1 & early Z1A also have carb IDs of 1472 & 1473

This list does not include the versions with accelerator pumps.

Starter/choke plungers

The starter/choke plunger is operated by the choke lever. When opened it allows more fuel to be drawn into the carburettor, enrichening the mixture. This plunger has a rubber seal at the tip which is supposed to seal and stop fuel delivery. However, over time this rubber seal becomes hard and deformed. This reduces the effectiveness of the seal which leads to excess fuel being drawn into the carb all the time and causes a permanent rich running condition. So, if your bike is running well, but always seems to have sooted spark plugs, then you should check your starter/choke plungers. If you can see a visible circular ridge in the rubber seats, or they are cracked or hard then they do need replacing. We offer aftermarket replacement starter/choke plungers manufactured by Keyster in Japan.

When carrying out a full carburettor refurbishment, we would always replace the choke plungers as a matter of course.

Pod filters or velocity stacks

When running pod filters or velocity stacks, you need to have air correctors fitted. If not, you will usually experience an off idle stumble or low end bogging which cannot be tuned out by changing jets or needle positions.

Blockages

Blocked pilot jets or blocked passages in the pilot circuit are also a common problem which can cause low speed running issues or bogging. Due to the tiny dimensions these are the first part within your carburettors to get blocked by crud in your fuel, or stale fuel hardening.

Float & fuel heights

Actual float bowl fuel heights being set correctly are essential for good running and to avoid leaks and overflows. Correctly set float heights does not always equate to the the correct float bowl fuel levels, so always check the actual float bowl fuel levels using the clear pipe method. Leaks from your carbs, as well as causing unsightly stains, can be a fire risk and depending on the cause, can lead to bad running. Leaks will usually be caused by degraded carb fuel tees, float bowl gaskets or fuel lines, as well as over high float bowl fuel level or splits in the brass overflow pipes in the float bowl.

We hope you have found this guide useful and informative and we hope that you will think of us when you need parts.

A lot of work has gone into making this article, so please do share it with this link as opposed to copying and pasting:

How to guides - Aire Valley Classics | Troubleshooting bad running

Got a question or comment about this article, or need some advice then please feel free to contact us.

Updated: 03/10/23